Why use Slag Cement in Concrete?

Concrete proportioning is the selection of proportions of ingredients to make the most economical use of available materials to produce concrete of the required properties.

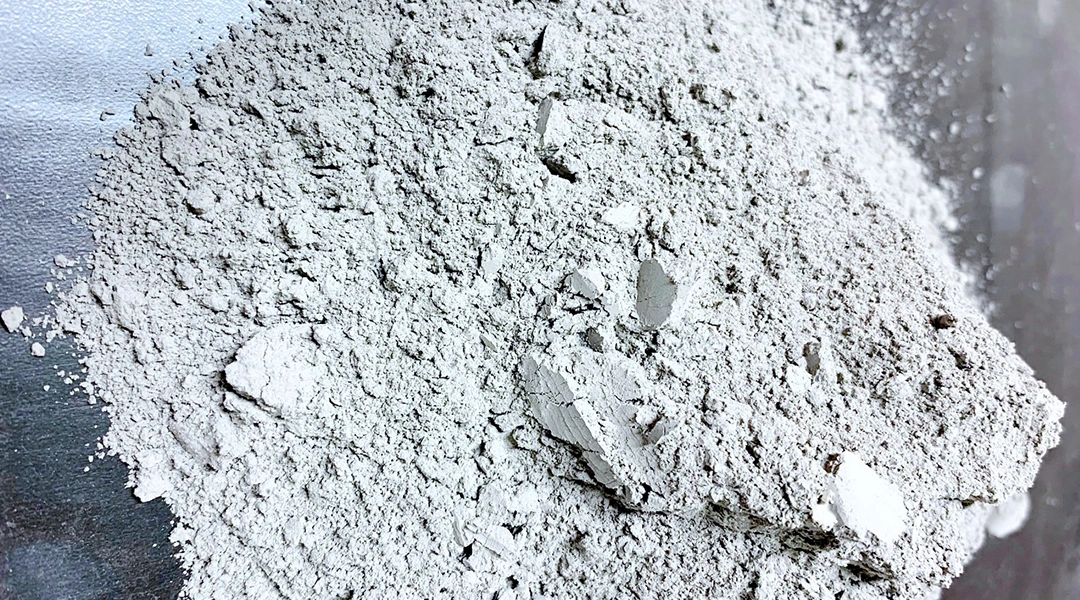

Why use Slag Cement in Concrete?

In concrete, slag cement may be proportioned from 20 to 80% depending on the application. It is substituted for portland cement on a one-to-one basis by mass. The proportion of slag cement used is usually dictated by requirements for strength, durability, time of set, heat generation, or the resistance of the concrete mixture to alkali silica reaction (ASR) and sulfate attack. The range of replacement rates for various applications are shown in Table 1, though specific replacement rates will vary with the particular circumstances.

Proportioning Concrete with Slag Cement

Concrete mixtures containing slag cement should be proportioned according to ACI 211.1. The specific gravity of slag cement ranges from 2.85 to 2.94, depending on the slag source, as compared to 3.15 for portland cement. The difference in specific gravity means a greater volume of slag cement will be used to replace the same mass of portland cement. The larger percentage of fines usually provides mixtures that are easier to place, finish, and consolidate. A higher percentage of coarse aggregate can be used to increase strength and reduce water demand

Information Sheetswithout affecting plastic properties.

In general, water demand for any given slump may be reduced up to five percent. Slag cement should always be included when calculating the

water-cementitious materials ratio. Slag cement is compatible with chemical admixtures regularly used in concrete. The effects of chemical admixtures in concrete containing slag cement are similar to their effects in ordinary portland cement concrete. Trial batches will determine proper admixture dosages. Slag cement does not contain carbon and therefore should not cause fluctuations in air content. Slag cement is also compatible with pozzolans such as fly ash or silica fume.

The percentage of slag cement to use for maximum strength development is usually between 40 and 50%. This is also normally the optimum percentage to use in concrete to provide the lowest permeability to the ingress of aggressive solutions and greatest resistance to ASR and sulfate attack. Slag cement used at replacement rates greater than 25% can cause an increase in time of set. The lower heat evolution characteristic of slag cement in the summer is beneficial because it allows more time for placing and finishing concrete. In the winter, increased time of set, occurring with higher percentages of slag cement, can be offset by use of chemical admixtures or heated materials.

Re-Proportioning Mixtures with Slag Cement

Most producers have a selection of mixtures already in use. A simple way to incorporate slag cement is to select a conventional mixture that has demonstrated a satisfactory performance level, based on criteria such as compressive strength, flexural strength, or permeability. Trial batches of equivalent mixtures containing slag cement at various levels should be evaluated for the desired performance characteristics